“The Circular Economy is now underway, and business’s implementing the design principles will benefit faster.”

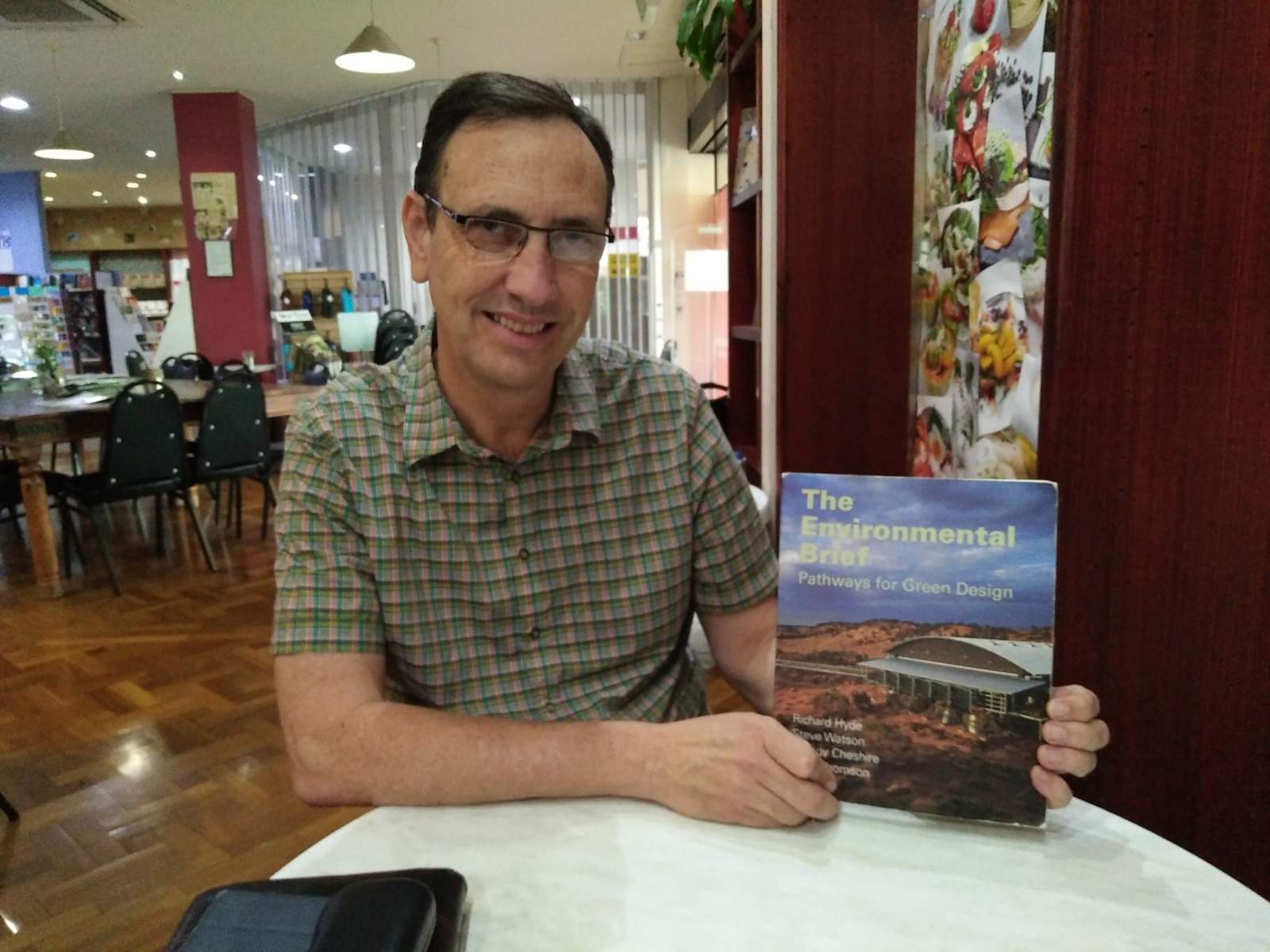

We are thrilled to announce our latest speaker to join us at Circularity, the founder of Eco Effective Solutions, Mark Thomson! He has helped design work and living spaces throughout Queensland while collecting multiple architecture awards and securing many Greenstar and EarthCheck ratings for sustainability-designed projects. Mark has been a judge for the World Architecture Festival and Australia’s (Sustainability) Banksia Awards.

Hear him and others speak at Circularity this year on understanding the importance of design in shifting to a more circular economy: https://circularitylive.com.au/whats-on/circularity-conference/

First published at: https://thefifthestate.com.au/waste/mark-thomson-says-fast-fashion-runs-rampant-in-the-furniture-sector/

Mark Thomson is an author, sustainability consultant and recipient of multiple architecture, building and design awards. As founder of Eco Effective Solutions, a research, education, and design practice, he strives to deliver healthy and regenerative work environments.

Mark is a regular judge of the World Architecture Festival and the Australian Banksia Sustainability Awards and serves as a company director on multiple not-for-profit organisations including Responsible Wood and Micah Projects. And he is co-author of The Environmental Brief: Pathways to Green Design.

Earlier this year he was appointed project leader for the Furniture 360 project, after the Australian Furniture Association (AFA) was successful in securing a federally funded grant on product stewardship.

Coming after the successful AFA Chemicals of Concern project, which was finalised in 2021, the Furniture 360 project was conceived to address Design and Chemicals of Concern issues which required incorporation into a future Circular Economy framework.

“The reality is that an excessive amount of commercial furniture is sent to landfill each year and past industry product stewardship systems have been largely ineffective,” Thomson says.

“Our research has identified that more than 90 per cent of commercial furniture (and much of this is timber) sold in Australia has been disposed of in landfill sites across Australia. This has become an unacceptable societal problem.

“A circular economy would challenge the linear approach which most Australian manufacturing adopts.”

The Furniture 360 project aims to explore the process to transform and engage industry stakeholders toward circular economy outcomes.

All meaningful change occurs when people can envisage a better solution to a problem, he says. Climate change and environmental problems are now becoming alarmingly obvious and the desire to find solutions is now driving not only government but also our community to take strong action to adapt and mitigate outcomes for our future.

Parts of the furniture sector have adopted solutions similar to the fast fashion phenomenon…consumers are encouraged to just buy new and discarded past products which is not only wasteful in materials, but it is uneconomical for both our society and the environment

Thomson says the existing furniture sector has some great examples of sustainable and circular products, but that some parts of the industry have adopted solutions similar to the fast fashion phenomenon which has become a problem. Consumers are encouraged to just buy new and discarded past products which is not only wasteful in materials, but it is uneconomical for both our society and the environment.

“We collectively need to identify better solutions!”

For many stakeholders, the solutions may be simple, however for others there may need to be changes in the materials and methods which are currently utilised.

The Furniture 360 project has been engaged to complete seven stages or milestones which include:

To date, it has uncovered some alarming insights – including that the Australian commercial furniture manufacturing sector currently operates under different conditions and standards to imported products.

This has created an environment whereby cheaper and often inferior imported products are chosen over and above the well-made and regulated processes which local manufacturers are required to meet. Our procurement systems are not working to deliver quality to the market, with price rather quality often being the major driver of sales.

Originally posted at: https://australianfurniture.org.au/industry-opportunity-through-stewardship-system/

A resilient and sustainable furniture industry, with Australia positioned as a global leader in innovation, is the aim of a three-year programme to develop a commercial furniture Product Stewardship system with minimal financial impact on the industry.

The Australian Government has provided a grant through the National Product Stewardship Investment Fund for the Australian Furniture Association (AFA) to research, consult with industry and implement ‘Furniture 360’ – design for commercial furniture.

Getting design right also means not including harmful chemicals in the production process, which the AFA identified through research and industry engagement undertaken in 2021. Future legislation will cement the findings and the industry is taking the lead to be ready when it happens.

Clever design to increases furniture’s life cycle, make it easier to repair and maximise the use of environmentally friendly materials is just of the many potential solutions.

‘Furniture 360’ Project Leader, multi-awarded eco-architect, Mark Thomson, says the stewardship system will help furniture businesses improve their triple bottom line and optimise resource yields by reusing products, components and materials in a closed loop system. This will aid in resolving some of the supply issues encountered during the COVID pandemic.

‘COVID has been a real showstopper. It showed us that our reliance on overseas materials can lead to supply shortages and has focussed our attention of resource flows, from extraction of raw materials through to end-of life scenarios.

It is estimated that more than three million square metres of commercial space is turned over annually, resulting in about 30,000 tonnes per year of commercial furniture waste. 95% of this furniture ends up in landfill.

‘Furniture 360’ will enable industry to better understand the benefits of locally sourced, quality materials in the supply chain, expanded services to extend product life, and reuse, redistribution and recycling strategies for a more sustainable ‘closed-loop’ approach to furniture manufacture.’

The AFA, in consultation with the furniture industry, will create a design-focussed Stewardship System, Stewardship Council, and training and accreditation programmes. Circular economy standards will be modelled on successful international programmes, like the UN’s Sustainable Development Goals.

‘A positive outcome for the industry is that it can leverage Australia’s richness of quality resources by adding triple bottom line social, environment and financial value. ‘Furniture 360’ is about opportunity – an opportunity for industry to realise considerable commercial benefits from circular design and increased access to collection and recycling services.

At the same time, the project has an important role in educating and informing consumers that cheap and less durable products produced from finite resources, that are discarded and need replacement, come at too great a cost for the customer, the planet and for less privileged overseas communities.’

Furniture 360’s objectives include increasing the quality and durability of products, by enhancing manufacturing standards, the efficient use of environmentally friendly materials, designing out the use of harmful chemicals, improved repairability and recyclability.

Central to the scheme’s success is engaging the entire furniture supply chain, including designers, suppliers, retailers, manufacturers, customers and recycling organisations, in the creation of a Furniture and Furnishing Product Stewardship network. The project will bring together market leaders and innovators across the furniture design, supply, retail, and manufacturing sectors to improve the design of commercial furniture, building Australia’s circular economy.

The project will be completed by March 2023.

Article first appeared: https://www.responsiblewood.org.au/builders-play-a-leading-role-in-sustainable-construction/

In addition, buying locally certified wood reduces our carbon footprint and supports local communities connected to sustainable forest management.

As Australian builders declare a climate and biodiversity emergency material selection plays an all-important role in protecting the planet.

In the latest Builders Declare webinar Mark Thomson, acclaimed eco-architect and director of Responsible Wood, outlined the case for buying locally and supporting timber that is certified under a recognised forest certification scheme.

Mark Thomson, an advocate for sustainable timber used the webinar to highlight the importance of 3rd party validation in the building and development sectors.

“I’m supportive of the Builders Declare and the Architects Declare movements and believe society is demanding protection of endangered ecosystems,” Mr Thomson said.

Mr Thomson highlighted that the Australian Standards underpin the supply of sustainable timber, with certification the only confident method to ensure that the timber you used had been secured and supplied in an ecologically responsible manner.

Responsible Wood certification uses the Australian Standard for Sustainable Forest Management (AS 4708) and is carried by Australian timber and paper companies committed to sustainable forest management practices.

In addition, Responsible Wood is a campaign associate of the Australian made campaign, and certification can be used to demonstrate that building materials are Australian Made and Australian Grown.

Mr Thomson believes that Australian timber is fit for purpose for Australian design and building and notes the timber industry provides excellent support services for the implementation of best practice design and building activities.

“Responsible Wood is the brand that I always ask for on my projects , as it satisfies my requirement to know, that the timber has been sourced from audited sustainably managed forests and chain of custody evidence can be provided,” Mr Thomson said.

For more information about the webinar and the Builders Declare movement please visit the Australian Builders Declare website.

Published 20 January 2021: https://www.pefc.org/news/building-with-timber-for-people-planet-and-a-better-future/

Our ‘PEFC Webinar: Building a better future with certified timber’ saw three experts in sustainable construction discussing the benefits of timber as a construction material.

Timber as a construction material is on the rise, as architects, engineers and builders around the world recognize its versatility, flexibility and benefits for people and planet.

Our ‘PEFC Webinar: Building a better future with certified timber’, that took place in December, saw three construction experts discussing the merits of timber.

Our first speaker was Mark Wayne Probert, Head of Sales for the UK and Ireland at Binderholz, a leading manufacturer of mass timber solutions.

Mark Wayne highlighted the importance of managing forests sustainably and the special characteristics of timber as a construction material.

He described how Binderholz pays attention to sourcing PEFC-certified timber and how the company uses 100% of a harvested tree, optimising the use of the raw material and protecting the forest resource.

Moving on to timber benefits, he explained “Timber is not like concrete and steel, which are cold to work with. It is warm and inviting even during construction. Timber is also great to work with, as it is quicker, safer and cheaper than other materials.”

Engineering technologies mean that mass engineered timber, such as Cross Laminated Timber (CLT) or Glulam, provide all the strength and safety required for small and tall buildings.

“The sky is the limit for the use of timber. Let’s build with wood and build for the planet,” he concluded.

Our second speaker, Paul Jarquin, is the President of REI Habitat, and a pioneer of wood construction in France. Using local and certified timber is a priority for his company.

“By building with wood, we can reduce a building’s carbon emissions by up to 60%,” he commented.

“This really is a game changer.”

Consumers are also starting to appreciate the benefits of timber.

“We are seeing an increasing demand for wood from consumers in France, particularly from the big cities,” Paul explained.

“Importantly, these consumers not only ask for wood, but also ask about its provenance. They want to know if it’s sustainable, and if it’s local. PEFC certification enables us to respond to their needs.”

Our third speaker, Mark Thomson, architect and Director of Eco-Effective Solutions, highlighted the benefits of timber buildings for the environment and the people living and working in them.

“Building with sustainable timber is eco-efficient,” he explained. “This means it creates more value with less environmental impact. Not only is it renewable, recyclable and reusable, but it also absorbs CO2 and has a positive effect on physical and mental health.”

Timber can have a calming effect on people’s stress levels and lower blood pressure. As Mark highlighted, educational and medical environments such as schools and health centres built with timber can improve the learning and healing processes.

At the same time, he emphasized the importance of choosing timber from a sustainable origin.

“It can only be stated that timber is renewable if it comes from a certified source,” he explained. “Unless you know the history of the timber, you may not be using the sustainable material that you think you are.”

Countries around the world are aiming for net zero carbon emissions by 2050 as a response to the Paris Agreement to keep global temperature rise below 2 degrees Celsius. The global construction sector has a key role to play in achieving net zero, and PEFC believes that building with low carbon certified timber is a key part of the solution.

Join our PEFC Webinar: Building a better future with certified timber to learn how timber construction supports climate mitigation and other global sustainability targets, and the important role that PEFC certification plays. The webinar is free to attend and takes place 16 December at 11:00-12:00 CET. Register now.

We will be joined by three experts in the field of sustainable construction and strong advocates of timber as a building material:

Mark Thomson, architect and Director of Eco-Effective Solutions, will focus in on why architects should be specifying certified timber. He’ll explain the inherent properties of timber in building, from their role in climate change mitigation, to their aesthetics.

Mark Wayne Probert from Binderholz will take us through the manufacturing journey, from sustainably managed forests to innovative mass engineered timber (MET) technology. Highlighting why the use of PEFC-certified timber is so important to the company, and showcasing MET projects.

Paul Jarquin, President and founder of REI Habitat, the first property developer in France to become PEFC certified, will focus in on the situation and opportunities in France. With the French government mandating that all new public buildings will be built from at least 50% timber or other natural materials, France is leading the world.

This webinar will provide you with a solid background on the sustainability wins for timber construction. You’ll come away with a better understanding of the social, environmental and economic benefits of designing and building with certified timber.

Our expert speakers will share with you a range of innovative projects, illustrating the numerous and varied advantages that building with certified timber brings.

Finally, the webinar will demonstrate why sourcing and building with certified timber is so critical, and how PEFC certification provides assurances of responsible sourcing.

While everyone is welcome, the webinar will be of particular interest to those working in the construction sector – whether you are already using timber, or are interested in finding out more about the sustainability advantages of timber construction.

From architects, specifiers and developers, to structural engineers, contractors, house builders and the timber supply chain, join us to learn how together we can build a better future with responsibly-sourced timber.